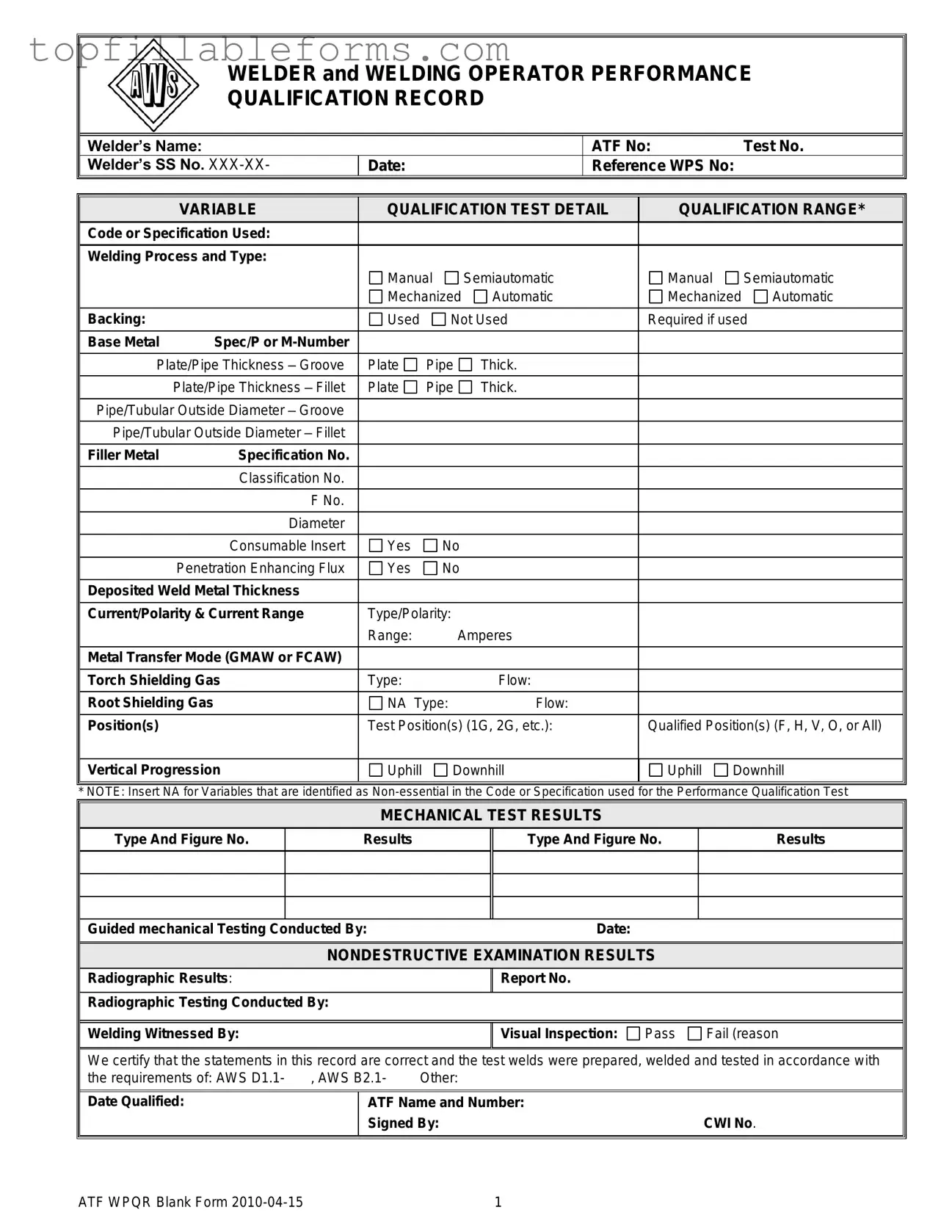

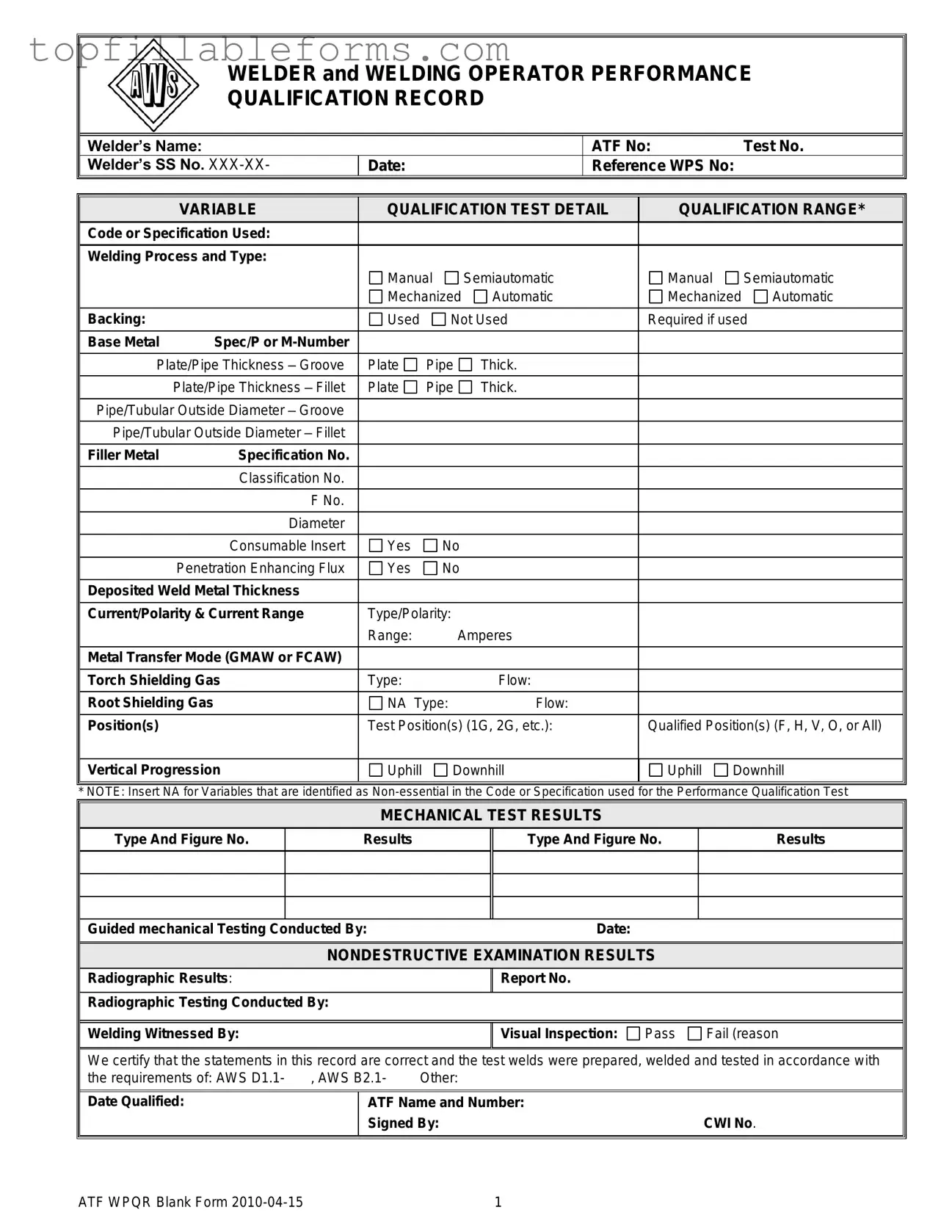

Printable Welder Performance Qualification Record Form in PDF

The Welder Performance Qualification Record form serves as a crucial document in the welding industry, capturing essential details about a welder's skills and qualifications. This form not only verifies the welder's identity and the tests they have completed but also outlines the specific parameters of the welding processes they are certified to perform. By maintaining accurate records, employers can ensure that their welders meet industry standards and safety requirements.

Open Welder Performance Qualification Record Editor Here

Printable Welder Performance Qualification Record Form in PDF

Open Welder Performance Qualification Record Editor Here

Finish the form now and be done

Finish your Welder Performance Qualification Record online by editing, saving, and downloading fast.

Open Welder Performance Qualification Record Editor Here

or

▼ PDF File